Category Archives: Pulp & Paper

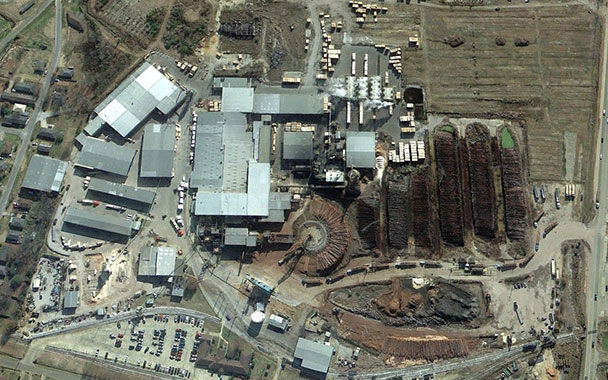

North Carolina Pulp & Paper

Wood yard modernization project: Mid-South Engineering provided engineering services to support the brownfield installation of a new wood yard from the entrance road to chip screening. Services included complete civil engineering, roadway design, custom scale house and new scale installation, and foundations for a new radial crane. Additional services included EPC vendor coordination and “balance of plant” piping and electrical engineering. Full-time on-site construction coordination was also provided for the duration of construction.

Alabama Pulp & Paper

Mid-South functioned as the EPC supplier for a complete rebuild of a transverse log slashing system that was originally installed in 1976. Demolition of the old system and installation of the new equipment took place during a 3 week annual mill shutdown. Mid-South was involved in all project aspects including design, procurement, construction management, operator training, start-up and commissioning. The project was recognized as the “Project of the Year” by International Paper due to excellence in project planning, installation execution, exceeding stated production goals and safety.

Maine Pulp & Paper

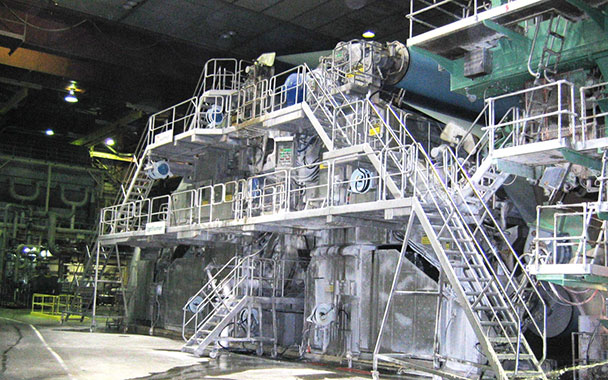

The project involved coater kitchen upgrades and significant modifications to a trailing blade coater.

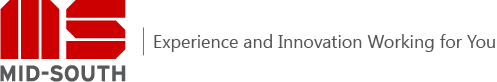

All new PM except for modified press and dryer sections. The project involved adding new cleaners and screening, new save-all, complete new twin wire forming section, press rebuild, dyer rebuilds, new moistening boom, new calendar stack, reel and winder, and a new roll wrapper. The project converted a paper machine that made lightweight directory paper to an SCA machine producing paper for rotogravure and offset printing.

Louisiana Pulp & Paper

Modernization of the Woodyard Optimization project.

Included detailed engineering: drum discharge conveyors, chipper infeed conveyors, bark collection convey, etc. Provided detailed engineering for the Bark Tripper at BTC2, Powerhouse Bypass Conveyor and Powerhouse Bypass Bark Storage.

Mississippi Sawmills

Bruce, Mississippi Plant

First curve sawing of dimensional lumber in the world up to 12-inch depths and 20-foot nominal lengths. This technology revolutionized the lumber industry.

Philadelphia, Mississippi Plant

First lineal tree length scanner/optimizer that resulted in the ability to obtain the true shape and dimensions of a tree and then quickly simulate the best cutting patterns for making lumber. The result allowed the industry to maximize our natural and renewable timber resources.