Category Archives: Building Products

East Texas Sawmill

Mid-South Engineering was selected to provide comprehensive engineering services and owners representation services on a 360 MMBF sawmill in East Texas. Our work included the repurposing of an existing manufacturing facility into one of the most technologically advanced full-dimension sawmills in the country. This locally owned facility brought hundreds of jobs back to the area and Mid-South is proud to be a part of the initiative.Arkansas Sawmill

Mid-South Engineering was selected to provide engineering services on a 388 MMBF sawmill in Arkansas. Our work included the design of a new sawmill facility on property adjacent to an existing and operating sawmill complex. The facility quickly became a new “state of the art” sawmill that was built on an undeveloped “brownfield” area of property owned by the client. The engineering scope of work included engineering services, process design (civil, foundations, structural, architectural, electrical, equipment layout), quality assurance, purchasing assistance, pre-operation engineering services, and on-site construction coordination. This engineering effort was recognized by ACEC with numerous design awards.

South Carolina Particleboard Plant

Four separate projects combined to make one large plant expansion. Expansion of the facility allowed the plant to grow the capacity of its particleboard and thermally-fused laminate operations. The particleboard expansion will increase by 60 million square-feet annually. These investments will allow the company to meet the growing demand for particleboard and broaden its TFL design offering in the region.

North Carolina MDF Plant

This 340,000 square foot mega-MDF project involved relocating the majority of their equipment from Labaie, Quebec. Uniboard Moncure is the largest MDF/HDF production line in North America and was Uniboard’s first MDF facility in the United States. In addition to producing MDF and HDF panels in a variety of grades and sizes, the Moncure mega-site also includes particleboard and thermofused melamine panels production facilities making Uniboard Moncure a true ONE-STOP-SHOP facility for distributors; manufacturers of kitchen cabinetry; office and residential furniture; store fixtures; flooring; and molding.

Georgia OSB Plant

This OSB facility in Quitman, Georgia, produces a variety of sheathing, flooring, and specialty products. In 2002, it began a project to replace an aging debarking line. Due to excellent market conditions, the project quickly grew to include (2) debarking lines, new green bins, new heat energy system and environmental controls, (2) new rotary drum dryers, dry screening, a new 8’ wide multi-opening press, and a new finishing line. By the end of the project, capacity at the facility had doubled while maintaining a high degree of uptime due to phased construction and strategic start-up.

Arkansas MDF Plant

Mid-South’s Facility Design Involvement:

• Process Development

• Plant Layouts

• Site Work Design

• Utilities Design

• Mechanical Design

• Structural Design

• Foundation Design

• Electrical Power Distribution

Project Management Including:

• Scheduling

• Bid Package Development

• Receiving & Managing Quotations

• Vendor Communications

Construction Management Including:

• Site Construction Management

• Vendor/Contractor Coordination

• Vendor/Contractor Invoice Processing

• Vendor Communications

On-site Management Including:

• Construction Management

• Site Safety Coordination

• Mechanical/Electrical Construction Coordination

• Document/Drawing Controller

Tennessee Gypsum Wall Board Plant

Mid-South’s Facility Design Involvement:

• Process Development

• Plant Layouts

• Site Work Design

• Utilities Design

• Mechanical Design

• Structural Design

• Foundation Design

• Electrical Power Distribution

Project Management Including:

• Scheduling

• Bid Package Development

• Receiving & Managing Quotations

Louisiana Plywood Plant Modernization

Mid-South’s Facility Design Involvement:

● Area Layouts/Dimensional Control Drawings: Wood Handling, Vat Infeed, Lathe, Dryer, Lay-Up Line, Press, and Sawline

● Detailed Cost Estimate

● Mechanical Engineering and Design

● Civil Engineering and Design

● Structural Engineering and Design

● Detailed Bid Packages for major equipment including: Wood Handling, Lathe, Dryer, Lay-up Line, Press and Sawline

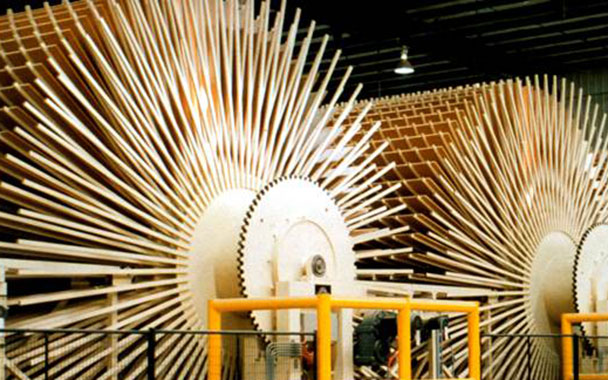

West Virginia OSB Facility

Largest OSB facility and the largest in North America when constructed, the greenfield facility was carved out of the hills in rural Heaters, West Virginia. The process design included many groundbreaking technologies including flail debarking, green screening, and four sets of dual drum triple-pass dryers resulting in the industry’s lowest dryer inlet temperatures. The press was the first 12′ wide multi-opening unit in North America.

Project Management Including:

• Process Design

• Structural Steel Design

• Purchasing Support

• Commissioning and Start-up Support

Georgia MDF Facility

This project started with an assessment and physical inspection of a shuttered facility in Las Vegas, New Mexico. The equipment and buildings were purchased and relocated to Willacoochee, Georgia after redesigning portions of the process and adding additional environmental control systems. This was the first MDF project for Langboard producing high quality MDF for the furniture and moulding markets.

Project Management Including:

• Civil Design

• Structural Steel Design

• Mechanical Design

• Electrical Design

• Purchasing Support

• Commissioning and Start-up Support